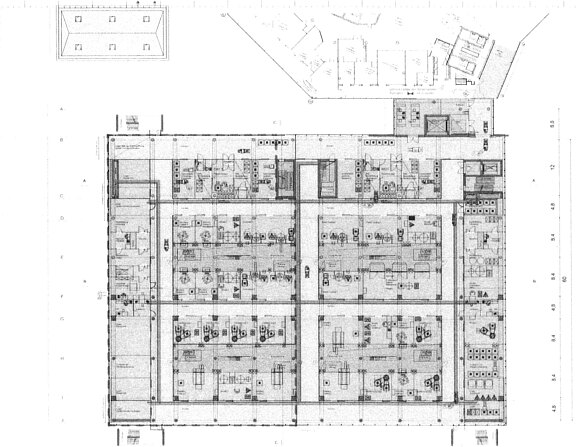

CLEANROOM PLANNING

KOP cleanroom planning not only includes a shell for a production step to be protected, but is part of a holistic interdisciplinary system with many parameters.

Based on a wealth of experience from a wide variety of production facilities, the following paramters are to be considered in their entirety:

- Development of a consistently compatible building concept based on a matrix structure for all trades.

- Hygiene concepts, material and personnel flow

- Skid and modular use of production systems

- Implementation of a sandwich principle in the allocation of production, building technology areas and distribution systems according to the principle of short direct routes of pipelines, air ducts and cabling. This includes, for example, the reduction of shaft installations.

- the implementation of the idea of a "production hotel - production on demand"

- the development of a new, highly modular, changeable cleanroom system for walls, ceilings, doors, media columns, airlock systems and new changing/ furnishing systems for the highest GMP requirements

- the development of a pressure-resistant, modular cleanroom façade

- a new TGA skid system for exchangeable or retrofittable ventilation units and tray systems

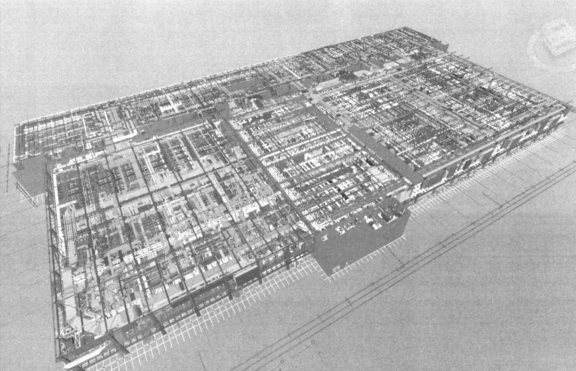

GENERAL PLANNING

KOP General Planning comprises all planning services required for the realisation of the building project. Holistic planning reduces the interface between the client and all project participants to one contact person.

Factory planning is a complex iterative process. Process architecture, production and building technology, economic efficiency and general conditions under building law lead to a holistic result. As general planner, KOP assumes overall responsibility for the planning project.

The advantages of the holistic planning approach are:

- Optimised planning and implementation

- High technical and economic efficiency

- Cost and schedule reliability

- Compliance with budget limits

- One contact person and one contract for the client

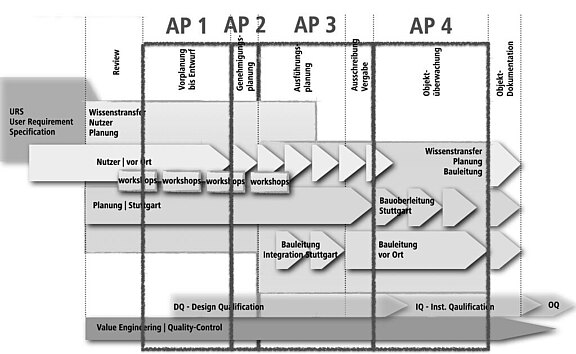

SERVICE PHASES HOAI 1-9

KOP Construction Planning includes all architectural services required for the implementation of the project.

- Basic evaluation

- Preliminary planning with cost estimate

- Draft planning and cost calculation

- Approval planning

- Implementation planning

- Preparation of the award of contract, including determination of quantities and preparation of tender document

- Participation in the award of contract including cost estimate

- Project supervision (construction supervision) and cost control

- Project supervision and documentation

HOAI= Fee Structure for Architecs and Engineers

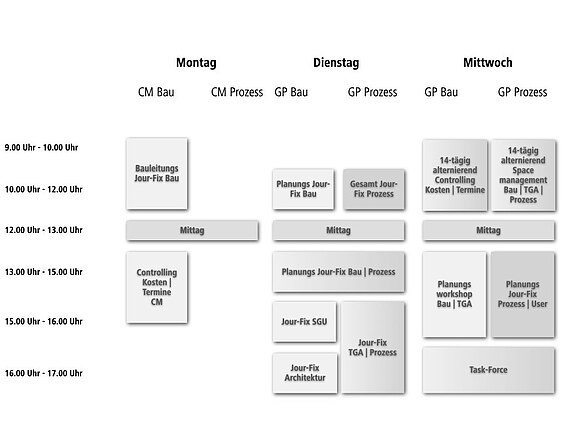

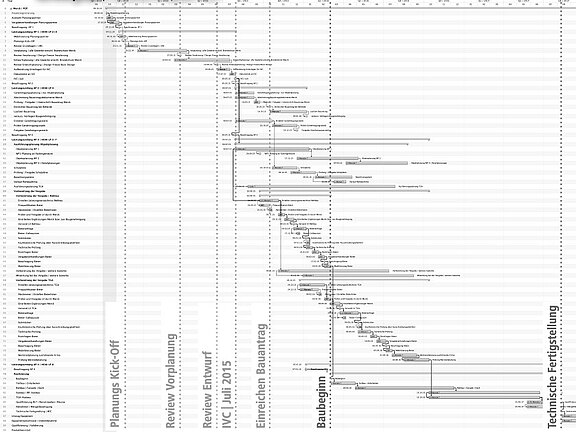

PROJECT MANAGEMENT

KOP Project Management aims for an effective approach in planning and execution that also benefits from the experience of projects realised so far.

Every factory is characterised by uniqueness. Especially industrial buildings in technically demanding industries place high demands on project know-how. KOP takes on the function of project management.

Whether accompanying or advising, quality, cost and schedule reliability are always the goal.

- Fiduciary assumption of building owner functions

- Contract management

- Decision management

- Central project contact point

PROJECT CONTROL

KOP Project Control is integrated into KOP Project Management. KOP organises, coordinates and documents the project and provides regular and reliable information on project implementation and upcoming decisions.

KOP Project Management comprises the components:

- Project organisation

- Quality control

- Cost control

- Schedule control

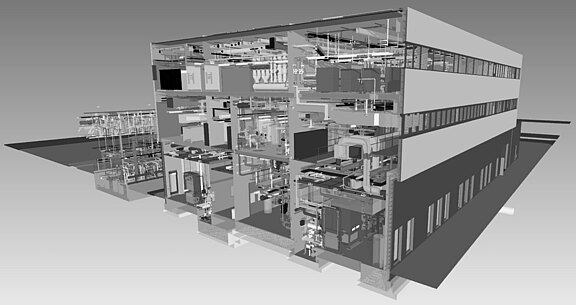

BIM – MANAGEMENT

KOP BIM - BUILDING INFORMATION MODELING includes the use of model-oriented CAD systems (e.g. Revit, TrimbleNova) during the complete planning phase, which significantly improves the project process. The bundling of building information in the virtual model forms a reliable source for all planning partners involved.

Right from the design phase, the basis is created to optimise the quality of the planning until completion.

Our BIM teams are characterised by long-standing employees with experience, regular further training and exchange of experience.

Internal BIM coordinators (buildingSMART certified), who keep an eye on quality across projects and optimise processes, complement the individual project teams.

The close cooperation and linkage with our planning partners also enables a smooth flow between the individual disciplines.

3D planning has been part of our expertise for 30 years. In 2015, we started to implement the BIM planning method in all our projects.

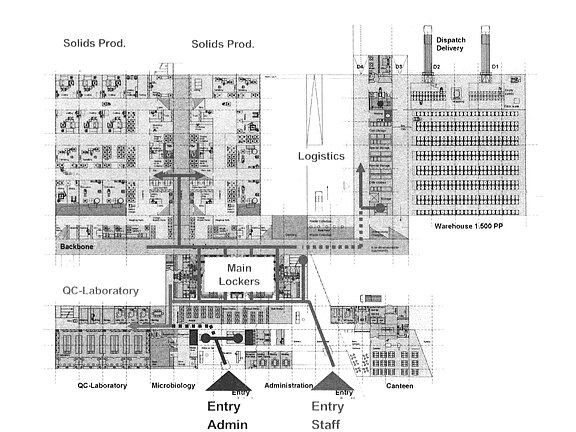

PROGRAMMING

KOP Programming includes, among other things, the building blocks of systematic requirements analysis and preliminary technical planning. Thanks to many years of experience in industrial planning, KOP has extensive specialist knowledge of operational processes.

Based on the operating and process sequences with their various requirements, the individual work steps and areas are methodically optimised.

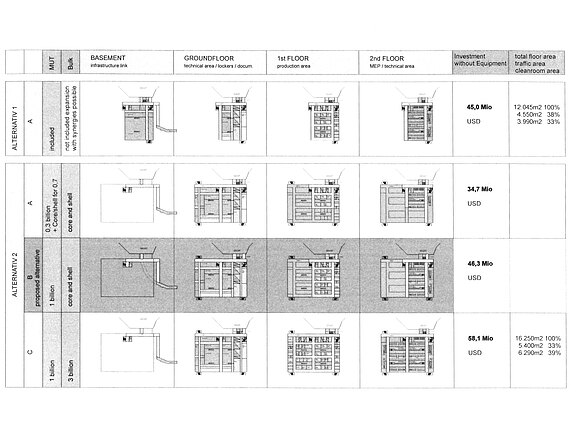

FEASIBILITY STUDIES

KOP Feasibility Studies analyse and evaluate the feasibility of the project under economic, technical and infrastructural aspects.

Is the project feasible? How realistic are the project budget and deadlines?

KOP project studies examine

- the technical feasibility

- the economic feasibility

- the organisational and time implementation

CONCEPT PLANNING

KOP Concept Planning is the building step on KOP Programming | Preliminary Engineering.

Operational processes, manufacturing and storage strategies are optimised and systematically implemented with proven and innovative industrial building technologies.

Our modular system approaches for cleanroom technology, process configurations, building services structures, building designs, façade systems, logistics, etc. are defined in the preliminary planning so that they can be implemented conflict-free, economically and reliably in the realisation and operational phases.

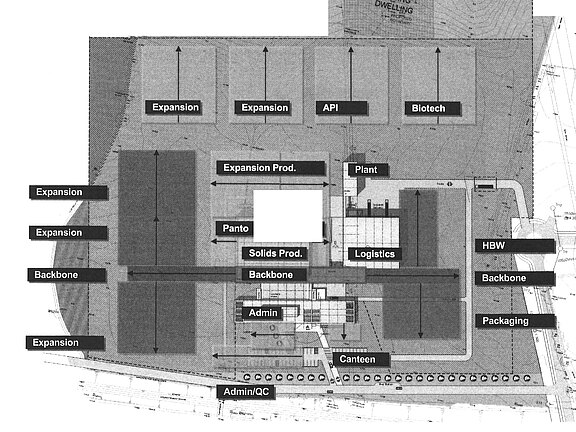

MASTER PLANNING

KOP master planning sets the course for the future, long-term development of the location.

Concrete future plans as well as visions and alternatives are planned through.

KOP optimises site planning and zoning concepts on the basis of the parameters determined. Future developments are taken into account - for the greatest possible long-term flexibility.

KOP master planning includes:

- Production strategies, material flow and logistics

- Economic aspects such as production costs

- Infrastructure, supply and disposal concepts

- Safety and environmental aspects

- Energy and sustainability concepts

- Expansion and third party use